SOLUTIONS

Design & Engineering Services

From concept to completion, Velosity seamlessly executes your manufacturing projects with unmatched expertise and capabilities. We have a long history of utilizing industry-leading design engineering services that ensure precision and efficiency at every stage.

Velosity’s integrated solutions address challenges across every aspect of the design for manufacturability and manufacturing processes. Engaging our team early in the design phase results in successful, cost-containment product execution. This early collaboration allows us to identify potential design improvements, optimize manufacturability, and ensure a smooth, efficient production process.

Our comprehensive services are tailored for a range of industries, including:

- Medical device manufacturing

- Defense manufacturing

- Industrial applications

Velosity’s cost-effective, high-quality tooling solutions meet the unique demands of each project.

WHAT WE OFFER

- DFM (Design for manufacturability) assistance

- Mold simulation

- Tooling design and manufacture

- Process development

- Validation / PPAP

- Program management

- Custom engineered solutions

DESIGN SUPPORT & ENGINEERING

Program

Management

At Velosity, we treat every project as a team collaboration, becoming an extension of your organization. Our engineering professionals leverage their expertise and your unique product requirements to develop solutions that exceed expectations.

By working closely with our clients, we deepen our understanding of their needs and provide innovative, high-quality solutions tailored to their specific challenges. The result is better communication, enhanced efficiency, and superior results.

DESIGN SUPPORT & ENGINEERING

Accelerated Engineering Solutions

Expedite tooling and product release with Velosity’s database modification services, reducing time to market and improving project efficiency.Velosity offers expanded, comprehensive engineering services beyond standard Design for Manufacturability (DFM) support. Our solutions streamline your projects and bring them to market faster.

Our accelerated engineering design services include:

- Design for Manufacturability (DFM) Support

Our engineers have expertise in thermoplastic and silicone injection-molded products and simple to moderately complex assemblies, ensuring optimal design for efficient production. - Database Modification

Expedite tooling and product release with Velosity’s database modification services, reducing time to market and improving project efficiency. - Material Selection

Leverage our extensive knowledge of thermoplastic, elastomeric, and silicone materials to select the best resin options for your application, ensuring performance and reliability.

Velosity’s enhanced engineering services overcome constraints and deliver high-quality results quickly and effectively.

DESIGN SUPPORT & ENGINEERING

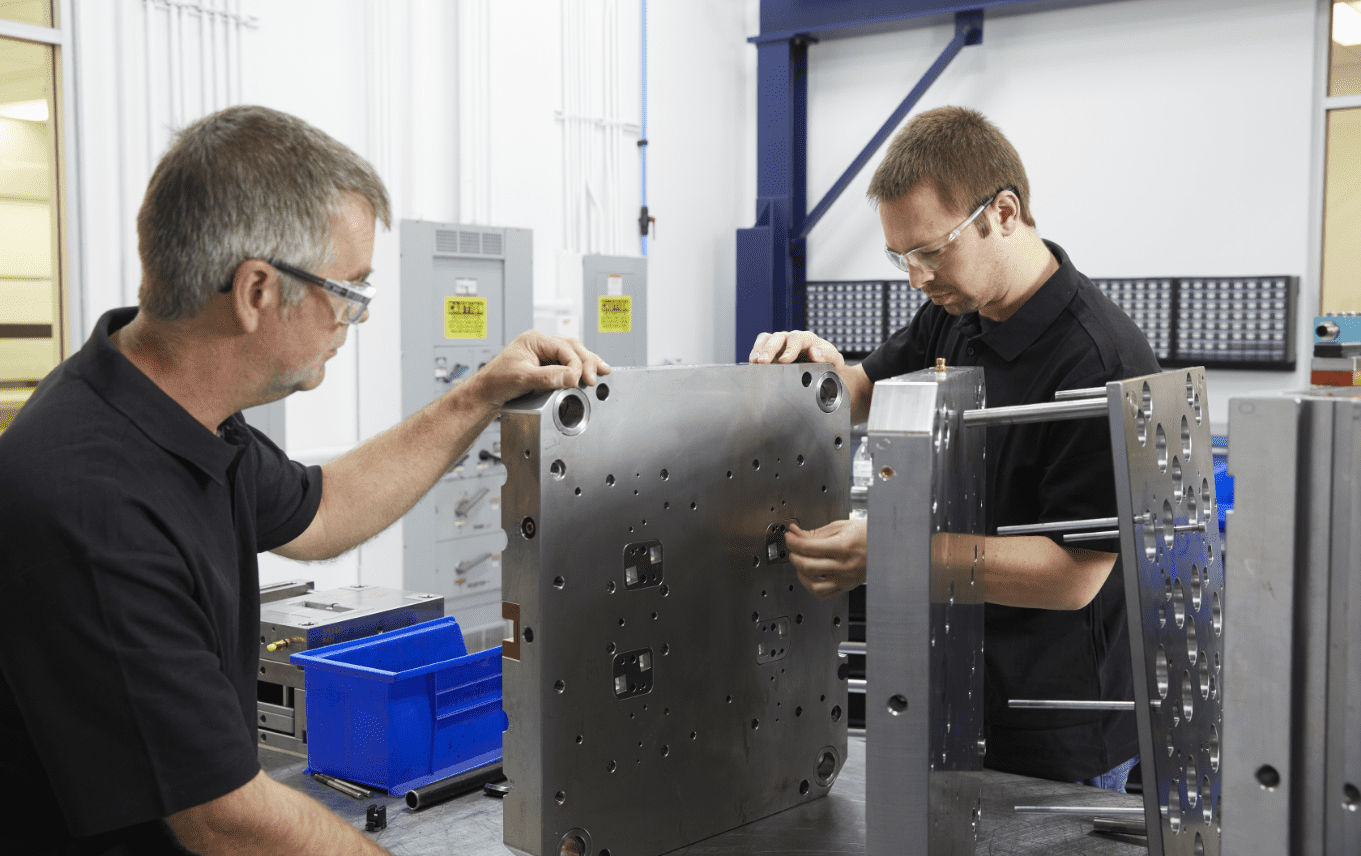

Tooling Design & Manufacture

The right tooling for your application depends on various factors, including part volumes, complexity, design confidence, material selection, and product lifecycle. Velosity’s tool design team helps you navigate these considerations to determine the best tooling solution for your needs.

- Lower Volumes: Master unit die (MUD) systems may be ideal.

- Similar Part Designs and Materials: Family tools can streamline production.

- Similar Part Designs and Different Materials: Interchangeable mold inserts may provide versatility.

- High-Volume Projects: Multi-cavity molds and hot runner systems can optimize efficiency.

- High-Cost Raw Materials: Creative tool design solutions can reduce waste and control costs.

Whatever your requirements, Velosity selects and implements the most effective tooling solutions to ensure the success of your project.

DESIGN SUPPORT & ENGINEERING

Design for Manufacturability

Velosity is a world-class leader in mold design and manufacturing. Our engineers and project teams excel in Design for Manufacturability (DFM) and Design for Assembly (DFA) support, with a particular focus on medical device manufacturing.

We collaborate closely to recommend design enhancements, component consolidation, and other strategies to reduce costs, optimize part performance, and improve manufacturability. This approach enables a smooth transition from design through qualification, validation/PPAP, and full production.

Velosity is also highly proficient in using Moldflow and similar injection molding simulation software to predict flow patterns and identify potential mold filling issues, such as sink marks or areas of high stress. Addressing these concerns early in the design phase saves time and reduces costs, ensuring efficient, high-quality production outcomes.

DESIGN SUPPORT & ENGINEERING

Process Development

At Velosity, our process development team applies Scientific Injection Molding (SIM) principles to deliver exceptional results. The journey begins with effective DFM, which drives superior tooling design and lays the foundation for robust process development. This comprehensive approach ensures production of high-quality, reliable products that meet and exceed expectations.

DESIGN SUPPORT & ENGINEERING

Validation

At Velosity, you can expect comprehensive validation and qualification support tailored to your needs. Whether following customer-defined, Velosity-developed, or collaboratively developed protocols, our team ensures a seamless and thorough validation process.

From metrology and component qualification to full IQ (Mold Development), OQ (Process Development), and PQ (Process Verification) validation, Velosity leads the charge in delivering best-in-class support. Our commitment to precision and reliability ensures your products meet the highest standards at every stage of the validation process.