SOLUTIONS

Tool Design &

Manufacture Services

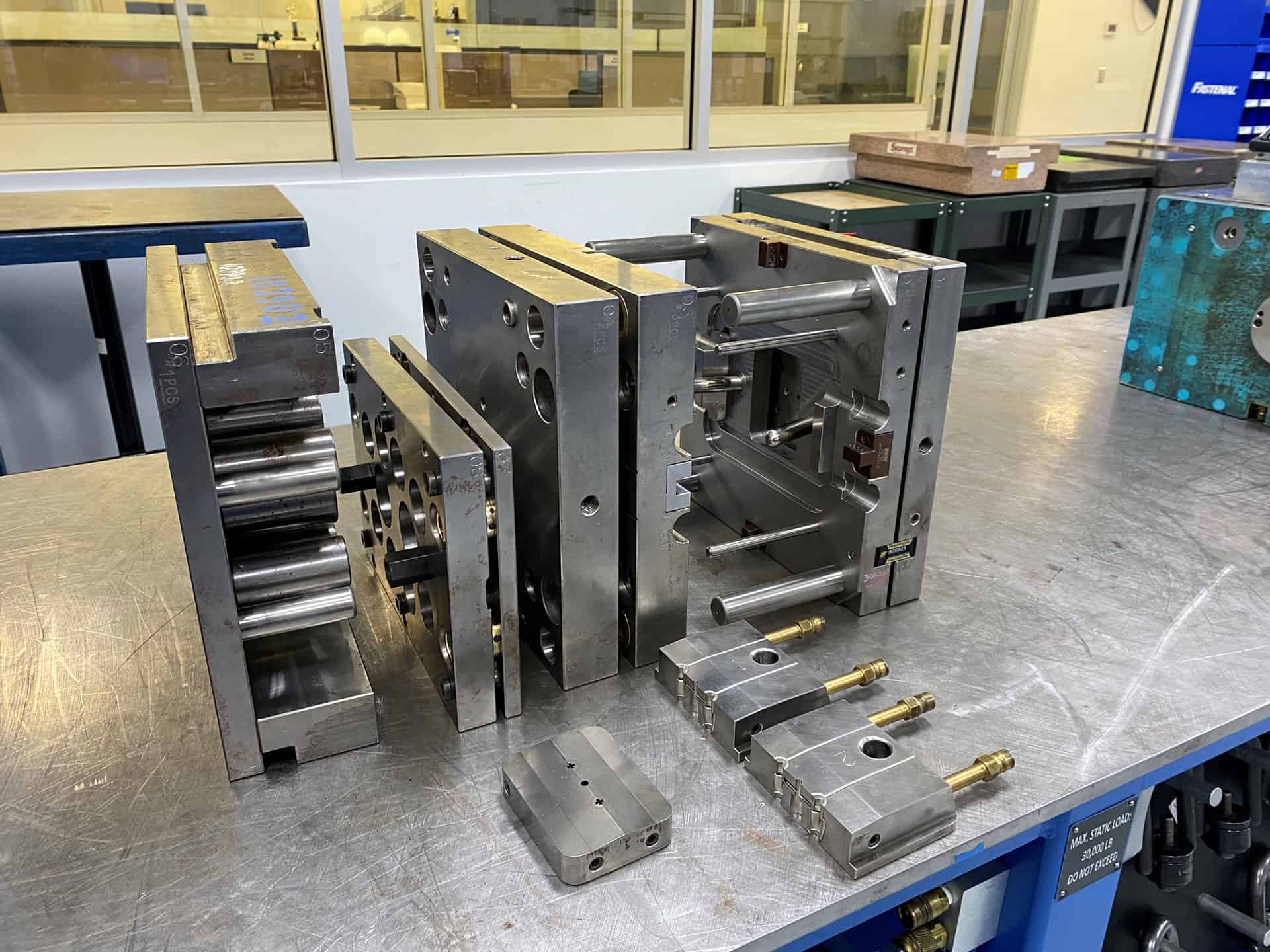

For over 50 years, Velosity has earned the trust of the industry’s most demanding customers—mold by mold—at our FL-CMD and Becker facilities.

Our customers rely on us for their most challenging and complex tooling and mold component needs. With specialized medical device, defense, and industrial contract manufacturing solutions, our experienced design and engineering team leverages advanced technology and best-in-class equipment to deliver precision and excellence in every project.

At Velosity, we prioritize your needs through meticulous consultation, attention to detail, and personalized services tailored to your requirements. Precision molds lead to precision components, and our commitment to quality ensures superior results every step of the way.

With a proven reputation built on trust, Velosity is the go-to choice for customers seeking unparalleled tooling and mold solutions. We can tackle even the most demanding challenges, delivering results that exceed expectations.

MOLD TYPES

- Multi-Cavity Molds

- Multi-Shot Molds

- Micro Molds

- Insert Molding Molds

- Silicone Molds

- Cold Deck for Silicone Molds

- Thermoset Molds

- Metal Injection Molds (MIM)

- Ceramic Molds

- Stack Molds

- Reel to Reel Molds

- In-Mold Labeling Molds

- Unscrewing Molds

- Servo Unscrewing Molds

TOOL DESIGN & MANUFACTURE

Advanced Tool Making

Velosity’s team of highly skilled engineers and mold makers utilizes the latest CAD/CAM systems to meet the evolving needs of our customers. Our expertise extends across all phases of project development, including part design refinement and mold design. We optimize product costs and outcomes by providing creative input and collaborative support. Velosity’s experienced engineers and mold makers offer valuable insights to help make the best possible decisions, delivering superior results for every project.

Velosity operates one of the largest captive tool shops in the United States. Our expansive capacity and vertically integrated tooling resources enable us to produce hundreds of tools annually, whether for use in our molding machines or yours. With our advanced toolmaking capabilities, you’ll experience streamlined processes, precision engineering, and cost optimization.

TOOL DESIGN & MANUFACTURE

Mold Making

Velosity has earned a reputation for manufacturing molds that run millions of cycles with precision and reliability. Our attention to detail and disciplined manufacturing practices ensure the production of precision components that deliver complete interchangeability.

These benefits translate to:

- Lower maintenance costs

- Longer mold life

- Decreased cycle times

- Consistent product quality

We’re committed to providing mold solutions that enhance performance and deliver long-term value for our customers.

TOOL DESIGN & MANUFACTURE

Thermoplastics & Elastomers

Velosity designs and builds tooling to support products that utilize thermoplastic and elastomeric materials. These materials meet the diverse needs of many markets, including medical devices, defense, aerospace, and industrial applications. Whether engineering-grade or non-engineering-grade materials are required, Velosity’s tooling solutions ensure precision, quality, and performance.

TOOL DESIGN & MANUFACTURE

Silicone

Velosity specializes in designing and manufacturing silicone molds for various industries. We help customers create hard-to-build silicone parts while enhancing product design for improved manufacturability.

We have developed and manufactured our own cold deck systems to ensure precision and efficiency in silicone molding. Silicone injection molding offers many advantages, including:

- Reduced cycle times

- Controlled flash

- Capability to produce over-mold components

- Multi-shot silicone components

TOOL DESIGN & MANUFACTURE

Conformal Cooling

We leverage conformal cooling technology to optimize the production of plastic parts with complex geometries, such as those with thin walls or intricate features that are challenging to cool evenly. Our engineers utilize state-of-the-art techniques during the mold-building process to design cooling channels that closely follow the contours of the part surface.

This advanced cooling method promotes faster and more uniform temperature control, efficiently conducting heat away from the plastic part. The result is reduced cycle times, improved part quality, less raw material usage, and enhanced production efficiency.

TOOL DESIGN & MANUFACTURE

Two-Shot

Velosity designs and manufactures various types of molds that require over-molding or two-shot injection molding processes. These processes are efficient and cost-effective for molding plastic parts with two or more plastic resins or colors in one operation. We’ve designed and built high-quality molds for these specific applications.

When you involve Velosity early in the Design for Manufacturing (DFM) process, our engineers consolidate part numbers to improve efficiency and reduce costs. Our extensive experience designing and building high-quality multi-shot tooling means we can meet the demands of even the most intricate applications.

TOOL DESIGN & MANUFACTURE

Metal Injection Molding

Metal Injection Molding (MIM) combines the best plastic injection molding and powdered metallurgy to produce precise, complex parts in large quantities. Velosity is a trusted expert in manufacturing high-precision, tight-tolerance, and complex MIM tooling.

We can even sample molds in the green state, allowing for early evaluation and optimization before full-scale production. These tools ship to our customers for high-volume manufacturing and post-molding processing. With over 20 years of experience in MIM tool production, Velosity delivers quality and reliability for some of the most demanding applications.

TOOL DESIGN & MANUFACTURE

Mold Building

Velosity began as a mold builder in 1965 and has maintained that core capability ever since. Multiple tooling shops within our organization give us complete control over the tooling design and manufacturing process. Whether you need a single cavity or multi-cavity mold, we can control the process every step of the way.

We also have one of the most rigorous mold maintenance programs that helps extend the life of your tooling assets, and we can perform mold maintenance in real time. This level of expertise and control sets us apart from the competition.