SOLUTIONS

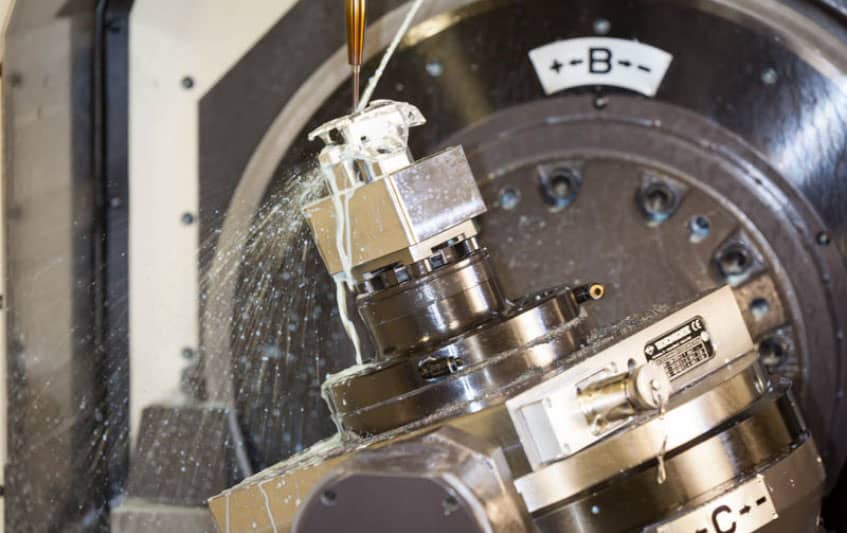

Precision Machining

Velosity can handle a variety of precision machining capabilities, including specialized capabilities for the medical industry, allowing us to fabricate complex geometries to tight tolerances. We serve a wide range of industries, including, but not limited to, aerospace, consumer products, defense, electronics, and medical. Our experienced craftsmen work with the best machinery, tooling, and software, and our superior design and engineering team raises the industry standard for first-class part design assistance.

What we do:

• Provide Design for Manufacturability (DFM) support to assist in optimizing your product designs

• High-speed, multi-axis machining

• Specialize in medical prototypes

•Support medium to high volume manufacturing

Add in our other vertically integrated capabilities, and you’ll find that we’re your one-stop shop for all your high-quality precision machined component and fixturing needs.

CAPABILITIES

- 3, 4 and 5-axis vertical and horizontal milling

- Swiss machining

- Dry machining

- Mill turning

- EDM services (wire and sinker)

- Fully automated CNC and EDM machining cells

- Tapping

- Deburring

- Drilling

- Laser marking

- Laser welding

- Swiss components

- Engineering services including Design for Manufacturability (DFM)

- Prototyping and NPI projects

- Additive manufacturing

- First article inspection

- Capability studies

- Robust supply chain management

PRECISION MACHINING

Materials

Velosity manufactures products from a variety of standard and exotic materials, including:

- Aluminum

- Brass

- Copper (including Beryllium)

- Stainless Steel Alloys (300 series, 400 series and 17-4)

- Castable Alloys

- Molybdenum

- Nickle, Hastelloy, Inconel, Invar

- Nitinol

- Tungsten

- Titanium and MP35N

- Polymers such as PEEK, Acetal, Ultem, polycarbonate and many others, including machining of plastic materials without the use of cutting fluid

- Composite Materials

Our arsenal of equipment includes some of the world’s most sophisticated technology, including 86 injection molding machines, 72 CNC machining centers, 25 EMC machines, 47 CNC Swiss machines, and 9 CNC turning centers. We use this state-of-the-art equipment to routinely manufacture parts with extremely close tolerance ranges, within .0001 of an inch or less.

PRECISION MACHINING

3/4/5 Axis Milling

Velosity supports your 3-axis, 4-axis, and 5-axis machined component needs by providing high precision and superior replicability. This is all based on performing up front design-for-manufacturability (DFM) to ensure optimized product designs. Our skilled designers and engineers are here to assist with all your project needs.

PRECISION MACHINING

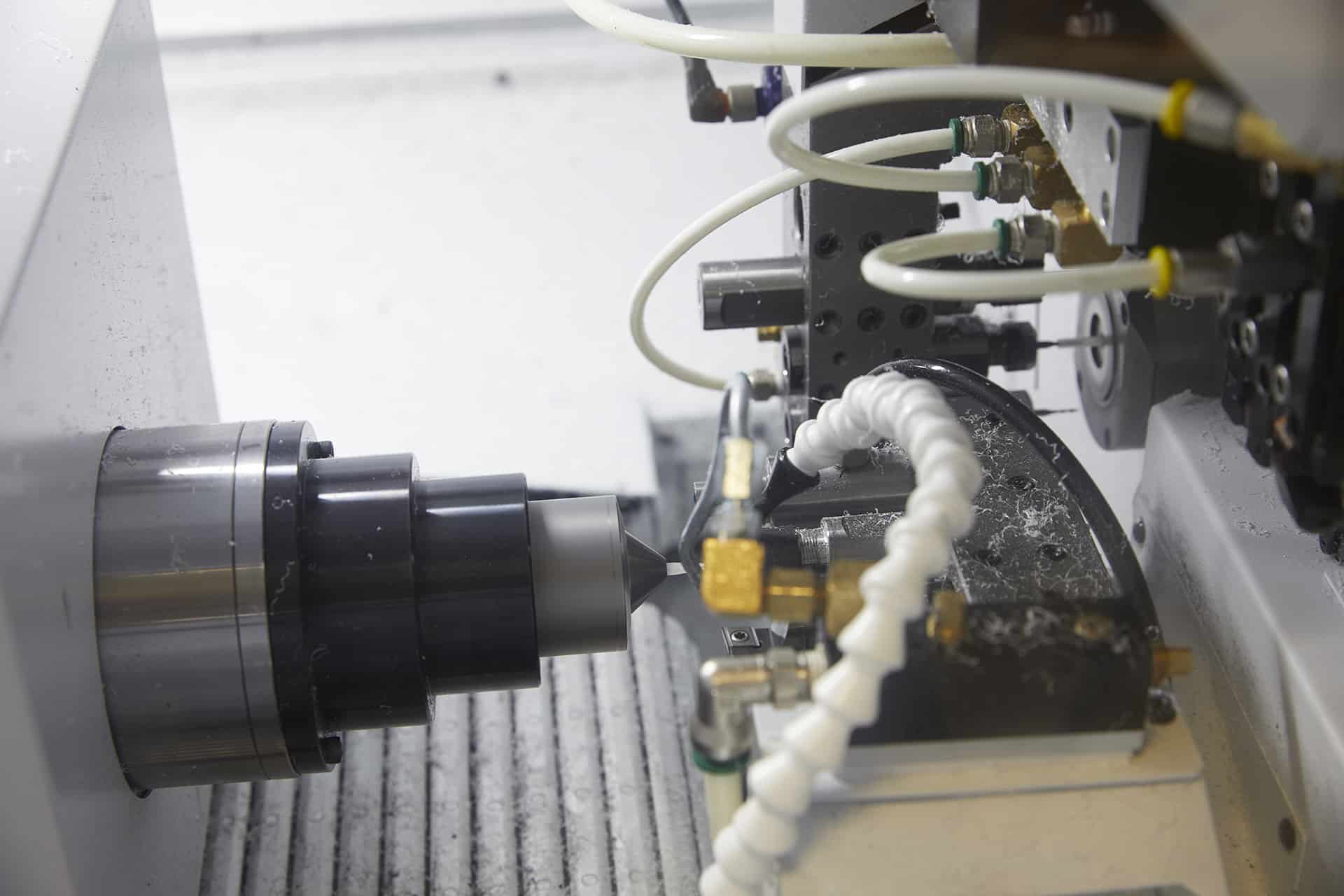

Swiss Machining

Velosity offers high-precision CNC Swiss Machining to support the medical device, aerospace, defense, and industrial sectors. We specialize in manufacturing Swiss components in a variety of materials, including:

- High-strength aluminum

- Stainless steel

- Brass

- Polymers

We proudly support our Armed Forces by providing flawless precision-machined defense components for the most demanding military applications.

PRECISION MACHINING

Coolant-Free Swiss Machining

Velosity continues our reputation for innovative manufacturing solutions for our customers. Dry Swiss machining (Coolant-free) is considered the cleanest manufacturing technique and a requirement in today’s Class II and Class III medical device machining industry.

Velosity has made facility investments to set up a dedicated white room to support dry machining. This ensures our customers can achieve the critical manufacturing objectives dry Swiss machining requires.

PRECISION MACHINING

Hard-Milling

Velosity’s highly experienced team is equipped with the latest and best machinery in the industry. Hard milling is used for both component and mold manufacturing. Surface finishes achieved often do not require any post-machining processing.

PRECISION MACHINING

Mill Turning

IOur mill-turning centers save our customers time and money each year by merging multiple operations into one, eliminating setup time, reducing operations, and enhancing part quality. Early involvement of the Velosity design team leads to a successful on-time launch and cost containment.

PRECISION MACHINING

EMD – Wire

Wire EDM (Electrical Discharge Machining) allows easy machining of complex parts and precision components. With faster processing times and superior finishes on even the most complex part geometries, Velosity provides its customers with a precise production and tooling experience every time.

PRECISION MACHINING

EDM – Sinker

Our sinker EDM equipment is ideal for hardened conductive materials and complex part details that are difficult to machine by other methods. This equipment is used to drill micro holes, create cavities, and make complex shapes in hardened metals. Velosity understands that manufacturing in highly regulated markets demands accuracy and precision, and we use only the best manufacturing techniques and equipment to achieve the tightest of tolerances for our customers.

PRECISION MACHINING

Graphite Machining

Velosity’s Graphite Machining Center delivers unmatched precision with advanced five-axis technology. Its zero-dust operation ensures a clean workspace, while exceptional surface finishes and tight tolerances make it ideal for industries like medical devices and defense.

PRECISION MACHINING

Prototyping

In the medical, defense, and industrial industries, prototyping plays a crucial role in product development. It allows manufacturers to validate design efficacy and manufacturability, making adjustments as needed before moving to full-scale production. Velosity specializes in guiding projects seamlessly from proof of concept to production, including the development of medical prototypes.

PRECISION MACHINING

Ready to Take the Next Step?

At Velosity, our precision machining facilities are ready to handle your project. Whether you’re in the market for precision machining for medical devices or for the defense industry, we have the skills, tools, and knowledge to meet your needs. Contact us today to see how we can bring your project to life.