SOLUTIONS

Tool Sampling &

Process Development

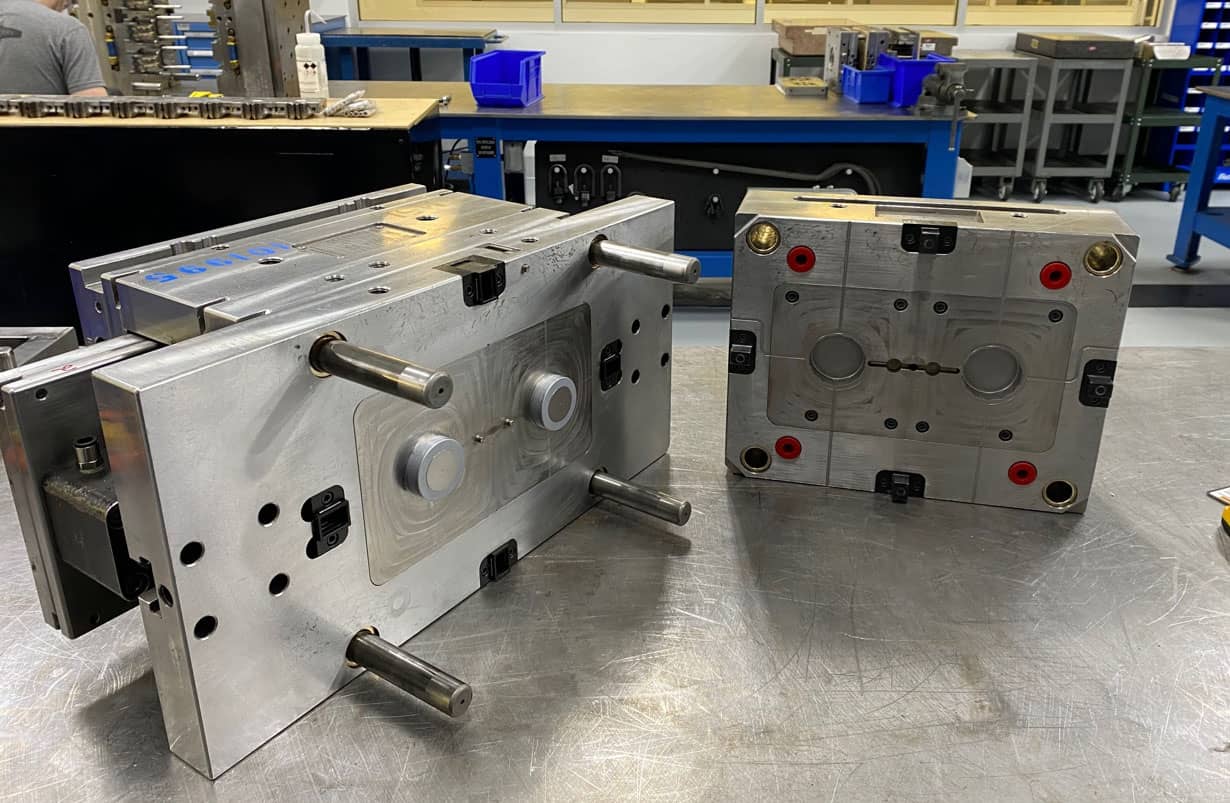

Velosity offers a comprehensive range of tool sampling options to help you achieve your tooling and process development objectives. Additionally, we can develop customized solutions for tooling trials, sampling, and inspection/validation that aligns with your specific project requirements.

With press sizes ranging from 20 tons to 715 tons and the support of our state-of-the-art metrology lab, Velosity is your vertically integrated partner for all product realization needs.

Our combined expertise in injection molding and precision machining—coupled with your unique requirements—ensures a successful product launch. This partnership cultivates a mutually advantageous relationship and ensures a smooth, satisfying experience.

By designing a comprehensive sampling and validation process, Velosity provides the data and insights you need to make informed decisions about your tooling and manufacturing process. Together, we’ll achieve outstanding results.

WHAT WE OFFER

- Turnkey tooling programs

- Design for manufacturability (DFM) assistance

- Consultation for moldability or manufacturability

- Tool sampling – injection molding of thermoplastic, elastomeric and liquid silicone rubber (LSR)

- A variety of mold sampling options to suit your needs

TOOL SAMPLING & PROCESS DEVELOPMENT

Tooling

Velosity can support your cleanroom requirements during tool sampling, process development, and production. We are compliant with all necessary regulations to provide sanitary products and have several in-house molding, assembly, and contract manufacturing clean rooms ISO Class 7 & 8. As a clean room assembler, we ensure meticulous attention to cleanliness and precision in every step of our manufacturing processes.

TOOL SAMPLING & PROCESS DEVELOPMENT

Thermoplastics

& Elastomers

Tooling is a critical component of the manufacturing process, enabling the production of precise, high-quality parts. Velosity designs and builds tooling tailored specifically for thermoplastics and elastomeric materials, supporting diverse industries such as medical devices, defense, and aerospace. This specialization allows us to provide customized solutions that meet the unique needs of our customers.

Thermoplastic Elastomers (TPEs) combine the mechanical elasticity of elastomers with the ease of processing thermoplastics, making them an ideal material for a wide range of applications. Velosity understands the many advantages of TPEs, including their cost-effectiveness, high design flexibility, and manufacturability.

TPEs are easily processed using conventional injection molding, blow molding, and extrusion techniques while maintaining exceptional quality. With Velosity’s expertise, you can achieve superior results for your most demanding projects.

TOOL SAMPLING & PROCESS DEVELOPMENT

Liquid Silicone Rubber

(LSR) Molding

Velosity is a leader in delivering liquid silicone rubber (LSR) injection molding solutions to meet the diverse needs of industries such as medical, industrial, aerospace, and defense. LSR injection molding is a specialized process that injects liquid silicone rubber into a mold cavity to produce high-quality, precise molded components.

Key capabilities of Velosity’s LSR injection molding include:

- Reduced cycle times

- Controlled flash

- The ability to produce over-mold components

- Multi-shot silicone components

Velosity’s LSR molding provides stable processes with enhanced part weight consistency. By employing exact dosing for every shot, our process ensures ultra-precise repeatability and uniform pressure, delivering the highest quality components with outstanding weight and size consistency.

With these advanced in-house capabilities, Velosity is fully equipped to support even the most demanding projects, ensuring exceptional results for every application.

TOOL SAMPLING & PROCESS DEVELOPMENT

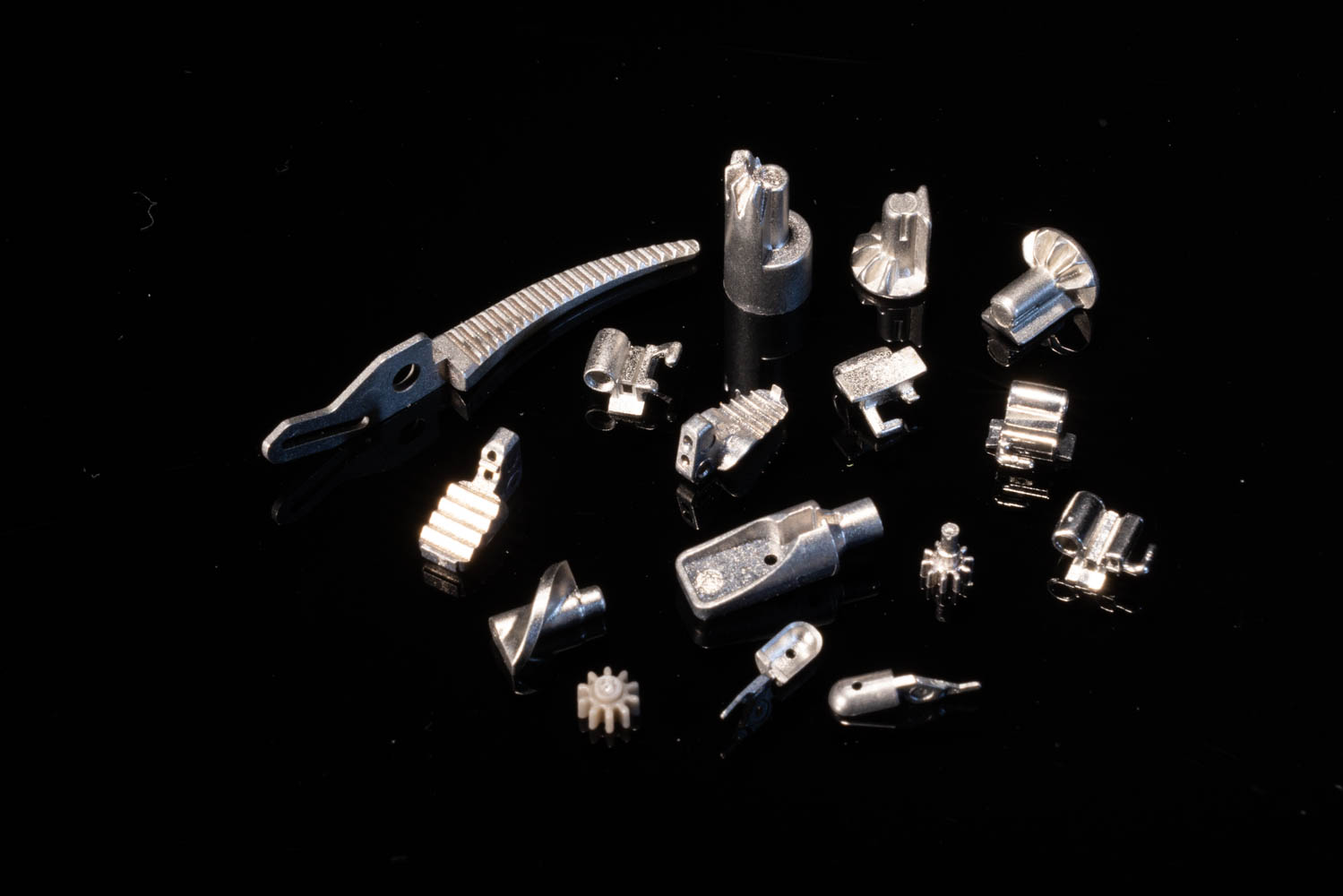

Micro Molding

As the demand for miniaturization grows, Velosity continues to refine its expertise in delivering precision micro-molded components and assemblies. Micro-molding involves the production of extremely small and intricate components with tight tolerances, making it essential to partner with a team experienced in this highly specialized field.

Velosity combines advanced technology, state-of-the-art facilities, and years of expertise to provide solutions tailored to your most demanding needs. Our focus is on delivering first-rate molds and tooling that consistently produce high-quality components and assemblies, ensuring your product-specific requirements are met with precision.